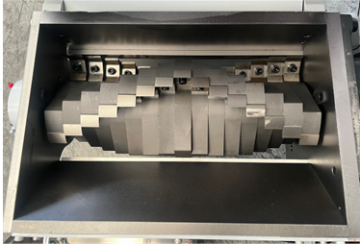

Granulator Model ITS430/280 used for short internal trial

Thanks to the staggered rotor blade design, it delivers precise, continuous cutting even on soft or fibrous materials, making it suitable for testing and lab applications.

Ideal for:

• Sprue and runner recovery from injection or blow molding

• Small plastic parts grinding

• Non-ferrous material reduction

• Textile scraps and low-tenacity materials

• Research and experimental use

Technical specifications:

• Rotor diameter: Ø 280 mm

• Rotor length: 430 mm

• Blade geometry: Staggered, high-efficiency

• Rotor blades: 45

• Fixed blades: 2

• Rotor speed: ~140 rpm

• Motor power: 3.7 kW – 400 V – 50 Hz

• Start with material in chamber: Yes, via high-torque gearmotor

• Weight: ~160 kg

• Compact structure: Easy to install beside processing equipment

The blades are designed for easy maintenance and can be rotated 180° for reuse before sharpening, with no need for special tools during reassembly.

Roter with staggered blades

Granulator with opened feeding hopper and screen support

Control panel following CE directives with n.3 security microswitches